As the leading manufacturer of crankshafts & diesel engine parts, it is the policy of Choikey to ensure that the quality of all products manufactured meets or exceeds customer expectations.

We subscribe to a philosophy of total quality performance in all our operations and tasks. Our policies, procedures & requirements with our systems place an emphasis on prevention rather than detection.

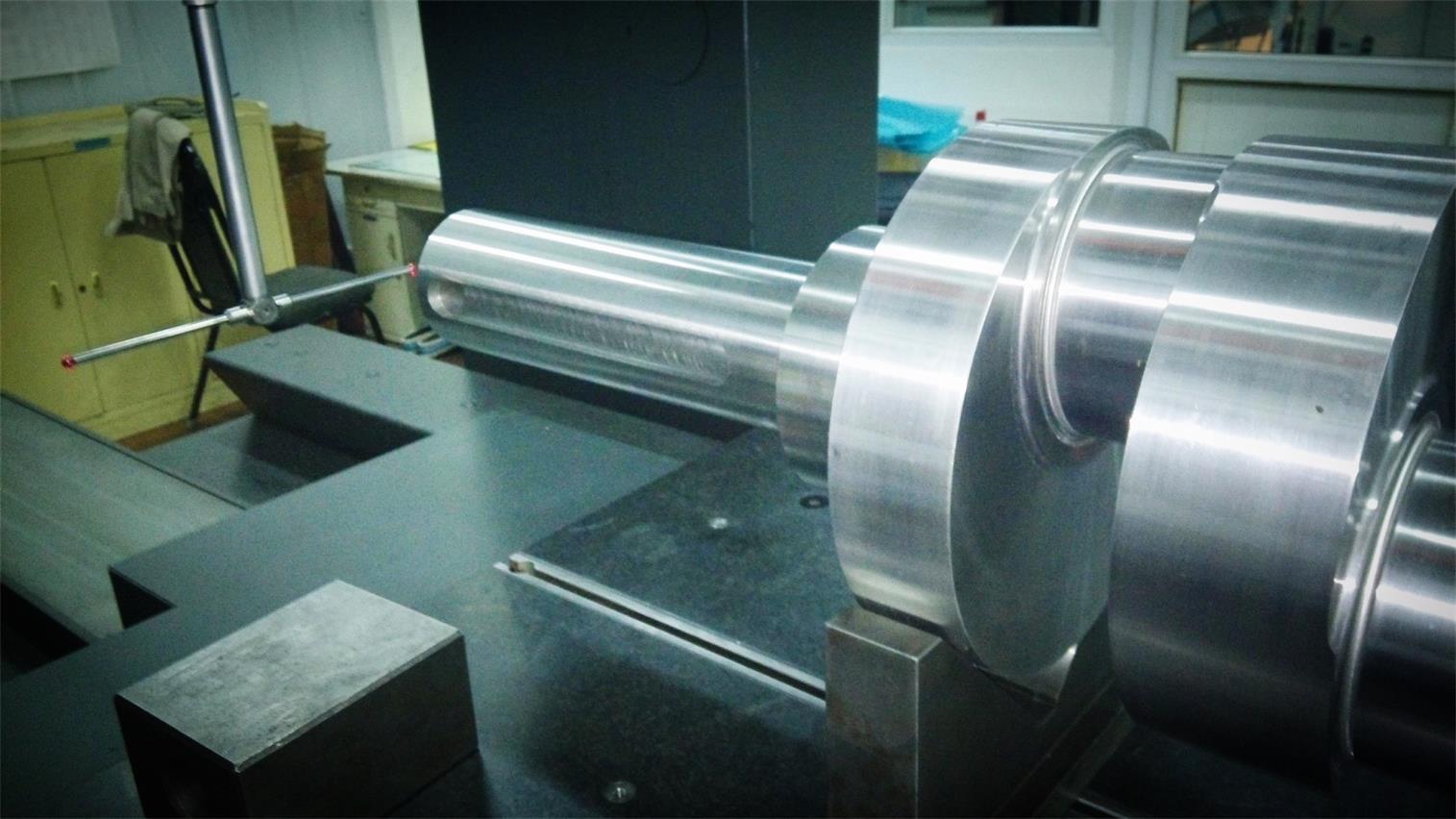

Choikey commits considerable resources to ensure that all products manufactured according to the stringent quality specifications required by our most sophisticated customers. On site, we operate an extensive range of quality testing equipment. All incoming raw materials, every batch of finished goods are inspected. We ensure traceability by keeping extensive records of the test results and can provide these to our customers if required. We also continuously improve our processes and the quality of parts manufactured by regularly evaluating test results.

Crankshafts quality control process in house as below:

1. Raw materials 100% incoming inspection;

2. Chemical composition analysis report for each furnace;

3. Mechanical property inspection report after heat treatment for each batch;

4. Hardness testing report;

5. UT 100% (for forging crankshafts);

6. MT 100%;

7. Final dimensions inspection reports 100%;

8. 3rd party inspection per customers' requirements.

APQP method utilized for the first artical sample.